This page is not compatible with Internet Explorer.

For security reasons, we recommend that you use an up-to-date browser, such as Microsoft Edge, Google Chrome, Safari, or Mozilla Firefox.

Battery Inspection and Development

Using Industrial Computed Tomography

Inspection Innovations

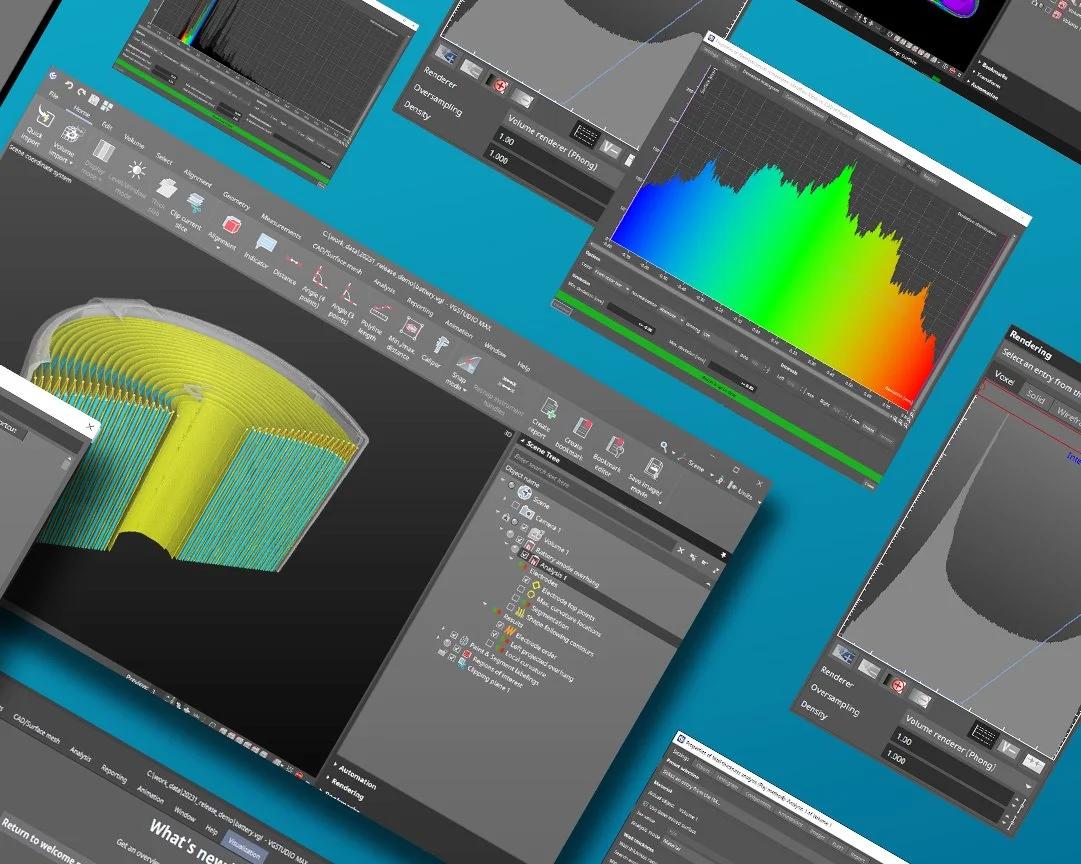

VGSTUDIO MAX enables battery inspection using industrial computed tomography (CT) to find and quantify porosity, inclusions, anode overhang, and delamination. Peer inside sealed batteries and conduct holistic, high-quality inspections—from R&D to end-of-line quality control, or even as part of an incoming goods inspection at an OEM.

Batteries play a crucial role in many of today’s rapidly evolving industries, posing an ever-moving target in terms of quality and development to companies in the automotive industry and related fields. For example, lithium-ion batteries (LIBs) are among the most expensive and safety-critical components in electric vehicles (EV), and they have a massive impact on vehicle range and safety. That makes batteries a hot topic in R&D, and researchers are aiming to optimize battery design as well as explore new concepts, such as solid-state batteries.

Regardless of end use, costs caused by poor quality in a battery can be astronomical, resulting in global recalls and double-digit losses in production. To remain competitive, market leaders are turning to the latest battery inspection technologies—that’s where we come in.

We’re here to help you not only attain but surpass your quality and reliability goals in this rapidly evolving industry. Let us show you how.

Your Challenges, Our Solutions

Battery Safety

Big Picture: Identify safety and quality issues during the manufacturing process, not after.

Ground Floor: Avoid a thermal runaway throughout a battery’s lifetime by checking your batteries for contaminations, measuring anode overhang, or detecting pores in the weld seam of the housing.

Battery Performance

Big Picture: Optimize high-performance batteries with higher capacity and power.

Ground Floor: Optimize the cooling system, from jelly roll constituents on a cell level to the entire module.

Battery Development

Big Picture: Achieve progress in battery design and microstructure characterization of the components.

Ground Floor: Characterize the structure of active material on the nano scale to gain deeper insight into the lithium-ion flow in a battery

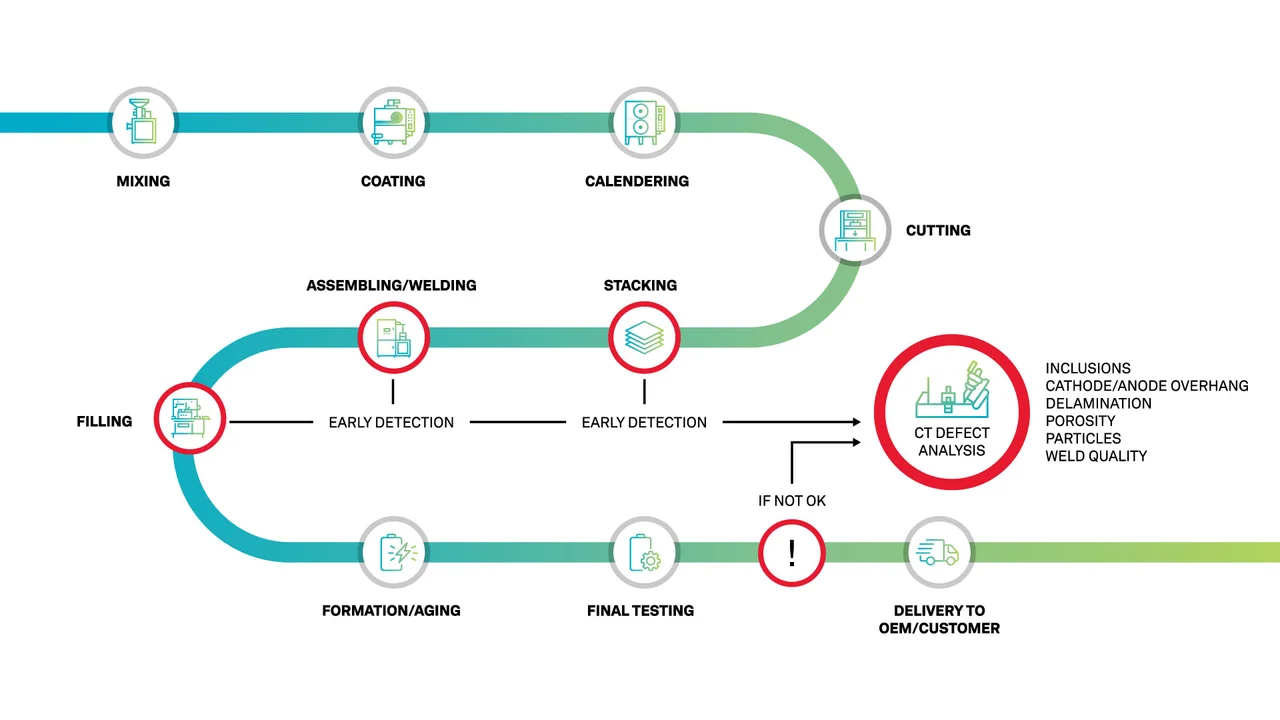

CT and Volume Graphics play a crucial role in battery production, from early detection to final quality tests.

Benefits

Increased Throughput

Enable reactivity and early defect detection across a wide range of defect classes for any battery type at various stages of the production cycle.

Faster Autonomous Defect Detection

Seamlessly transition from manual and semi-automated analyses in the lab to fully automated quality assurance in production, including optional manual operator reviews, machine learning, and deep learning solutions.

Cost Savings

Ensure maximum quality, predictability, and reliability, reducing high costs associated with non-quality and product recalls

The Volume Graphics Solution:

Battery Analysis with Computed Tomography (CT)

Let’s look at the wide range of analyses VGSTUDIO MAX can add to your battery toolbox.

-

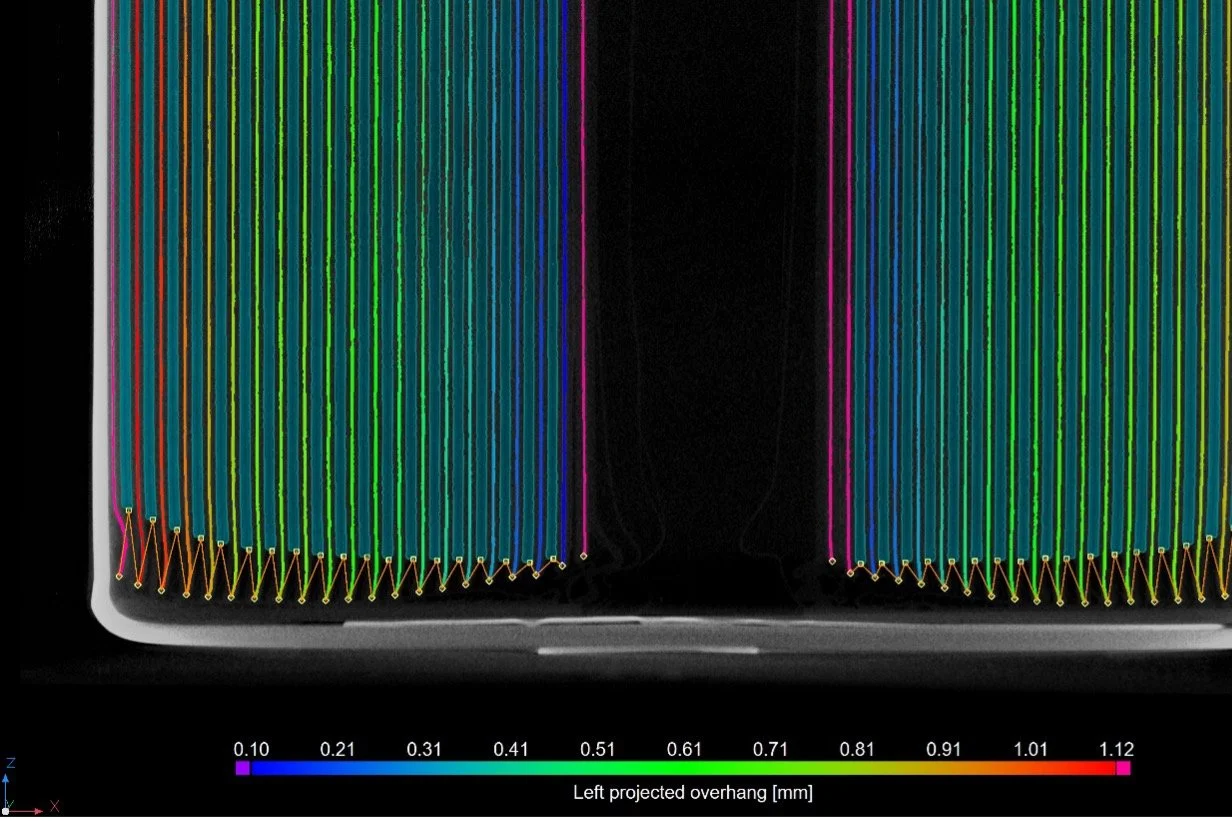

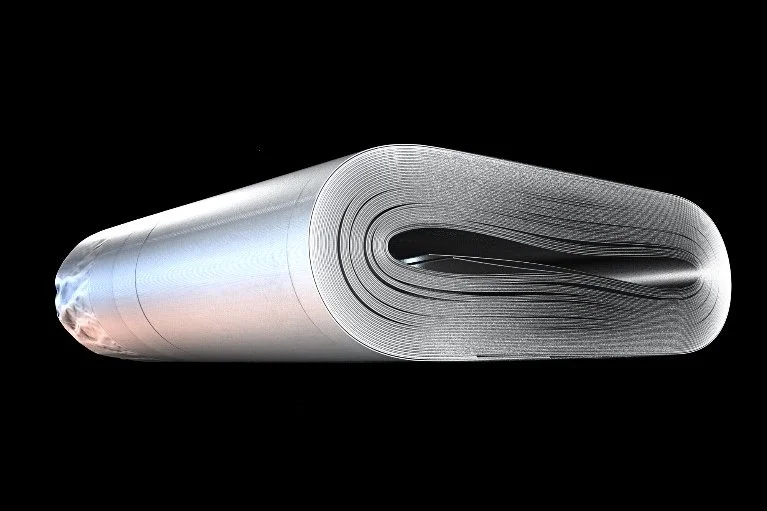

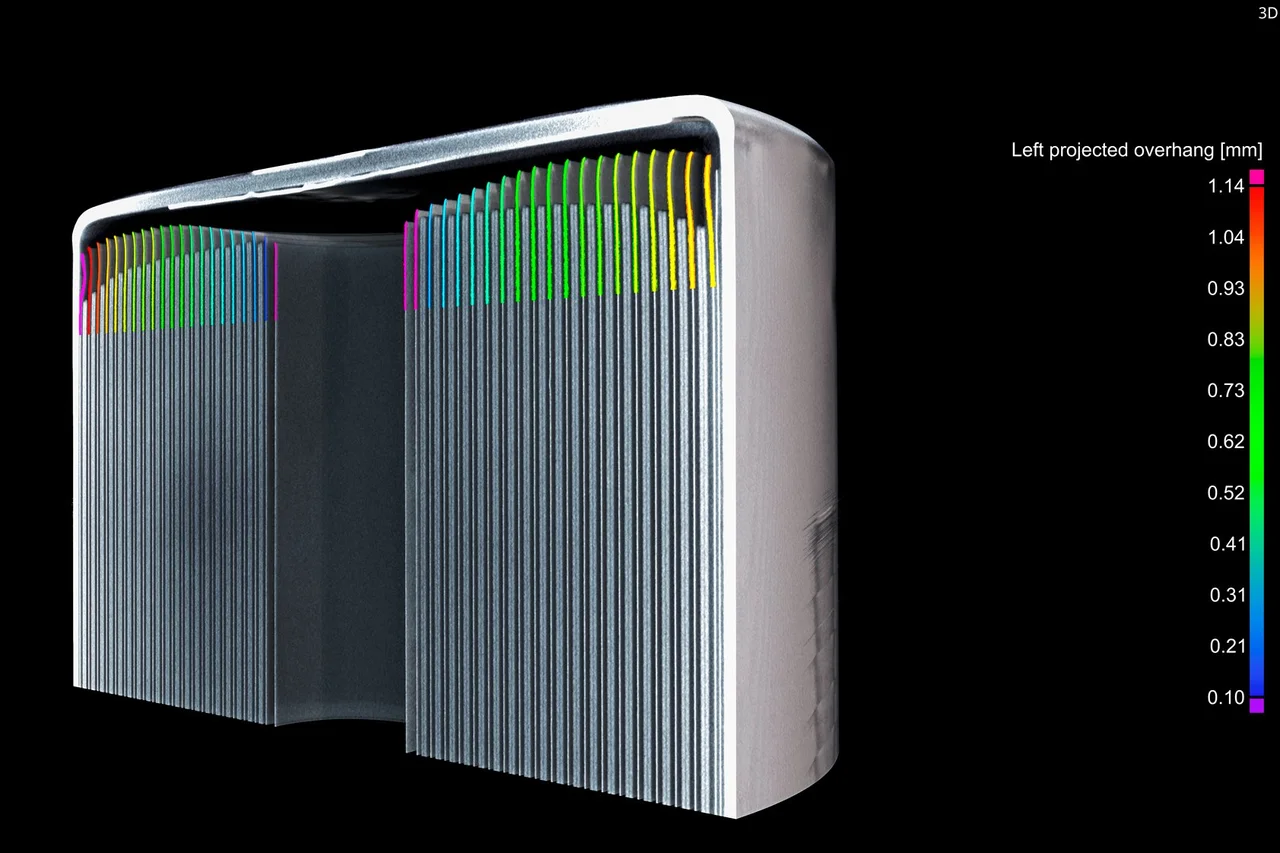

Anode Overhang

The anode-cathode overhang in lithium-ion batteries (LIBs) is a crucial safety criterion.

The Battery Analysis Module in VGSTUDIO MAX helps manufacturers and researchers measure and design anode-cathode overhangs that balance electrode utilization, current distribution, cycling stability, and safety considerations. By carefully controlling and optimizing the overhang, it is possible to improve the efficiency, capacity, cycling stability, and overall performance of LIBs.

Scan courtesy of Waygate Technologies

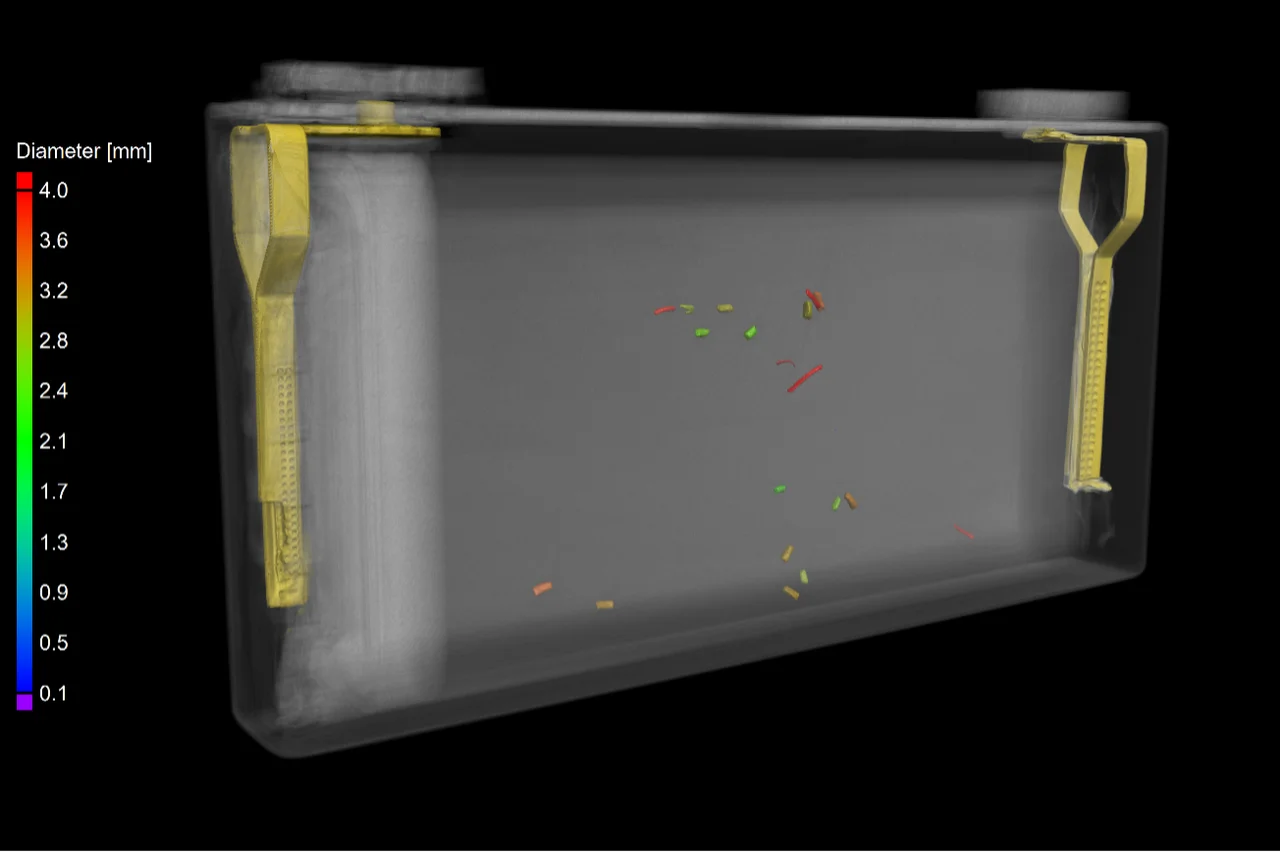

Foreign Particles

Foreign particles can make their way into a battery in many stages of production. The porosity/inclusion analysis in VGSTUDIO MAX allows you detect these particles and quantify their size and position to decide whether they are critical or not.

Scan courtesy of Waygate Technologies

Delamination

Delamination reduces the capacity and lifetime of the cell. Volume Graphics software can detect and visualize delamination not only during manufacturing, but also in later maintenance if delamination occurs after multiple charging cycles.

Scan courtesy of Waygate Technologies

Weld Seam Inspection

During prismatic cell production, porosity resulting from the welding may cause dangerous leaks and reduce battery function. The porosity/inclusion analysis in VGSTUDIO MAX will help you decide whether a pore is a reason for concern. By leveraging this analysis, manufacturers can identify and address porosity issues, ensuring the integrity and optimal performance of the batteries.

Additional Applications

-

R&D

CT scanning in combination with VGSTUDIO MAX empowers manufacturers to develop strategies for prolonging a battery's life, ensuring its efficiency, and improving its reliability for various applications. The nondestructive evaluation of electrode degradation, active material loss, and changes in structural integrity helps our understanding of how the battery's performance may degrade over time.

Moreover, new battery concepts, like solid-state batteries, may require an entirely new microstructure design, which means the analysis methods must be flexible as well. With VGSTUDIO MAX, you have an array of analyses that you can incorporate in easy-to-use workflows.

Scan courtesy of Nikon Metrology

Visual Inspection

Inspect parts visually by navigating through your data sets in 3D and perpendicular slices simultaneously. And the best part about it: All of this is possible with our free myVGL Viewer, which allows you to view any analysis results generated with VGSTUDIO MAX. The results can be immediately accessed via predefined bookmarks.

Serial Production

Battery cell manufacturers strive for high throughput while maintaining the highest possible quality and yield. To ensure battery quality, a series of electric tests are usually conducted as part of a systematic validation test protocol at the end of the production line.

However, these tests, while confirming the overall functionality, do not adequately assess the internal integrity of the batteries. It is crucial to identify any potential defects and make various measurements during the production phases to prevent accelerated degradation and reduced battery lifespan throughout their operating lifecycle. Ultimately, the inline measurements obtained at each stage of the battery manufacturing process can be collected to support quality assurance.

By providing real-time insights into the stability of the production process, this data allows can help engineers make informed decisions and take necessary actions to ensure the quality and efficiency of battery production.

Quality Checks for Second-Life Market

Safety and reliability are crucial factors when determining a battery’s suitability for second life applications. Nondestructive evaluation (NDE) combined with CT scanning and VGSTUDIO MAX is an invaluable tool for this. Gain a comprehensive understanding of the internal structure and integrity of the batteries and identify and characterize various defects, such as internal short circuits, electrolyte leakage, and electrode degradation. Learn more about a battery's active materials, electrode thickness, and overall cell uniformity, which assists in evaluating the remaining capacity and performance potential of the battery.

This approach also promotes sustainability by extending the lifecycle of batteries, reducing waste, and maximizing their value in energy storage systems and electric vehicle powertrains, among other applications.

Unleash the Potential of 3D Data Analysis

Battery Analysis Module:

Unlocking Technical Expertise

If you’re directly involved in the engineering or quality process, be sure to visit our Battery Analysis Module page for a more technical look at our software and machine learning capabilities.

Free 4-Week Software

Evaluation!

Unlock the power of 3D data analysis with our software. Start your FREE 4-week evaluation for VGSTUDIO, VGSTUDIO MAX, and VGMETROLOGY. Discover the difference Volume Graphics can make for your business today!

Hexagon’s Battery Solution

See how CT and Volume Graphics fit into Hexagon’s expansive solution for battery production and quality assurance.