This page is not compatible with Internet Explorer.

For security reasons, we recommend that you use an up-to-date browser, such as Microsoft Edge, Google Chrome, Safari, or Mozilla Firefox.

Structural Mechanics Simulation

with VGSTUDIO MAX

Perform finite element (FE) stress simulations directly on computed tomography (CT) scans. The structural mechanics simulation features in VGSTUDIO MAX provide an easy-to-use simulation model that is particularly suitable for highly complex structures such as foams, lattice structures, or components with microporosity, since no geometry-conforming mesh is needed. With one click, you can include the results of a porosity analysis to simulate stress concentrations around defects. Results have been validated against experimental tests and classical FEM simulations.

Structural Mechanics Simulation Features

Mechanical Simulation Directly on CT Scans

Working directly on voxel data, our easy-to-handle finite element (FE) simulation software:

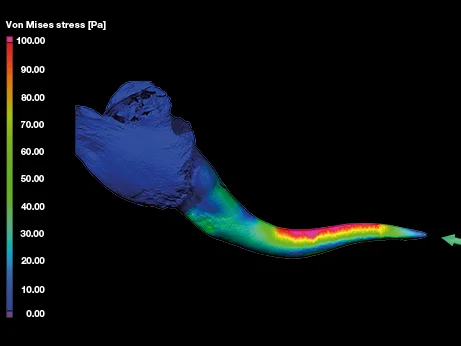

- Can be used to apply static mechanical loading by choosing between directed force, torque, and pressure.

- Can be used to simulate material probes as well as components for both mono- and multi-materials with linear-elastic material properties.

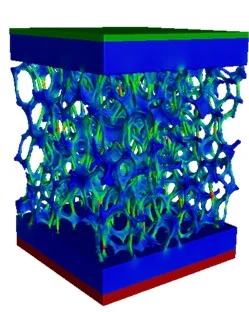

- Makes it very simple to build simulation models even for highly complex structures such as foams or components with microporosity, as well as biomechanical structures.

- Uses the sub-voxel accurate, local adaptive surface determination in VGSTUDIO MAX.

- Calculates stress concentration around microdefects by including the results of a porosity analysis run using any algorithm in VGSTUDIO MAX with one click.

- Provides a seamless workflow from segmentation to structural simulation in one software.

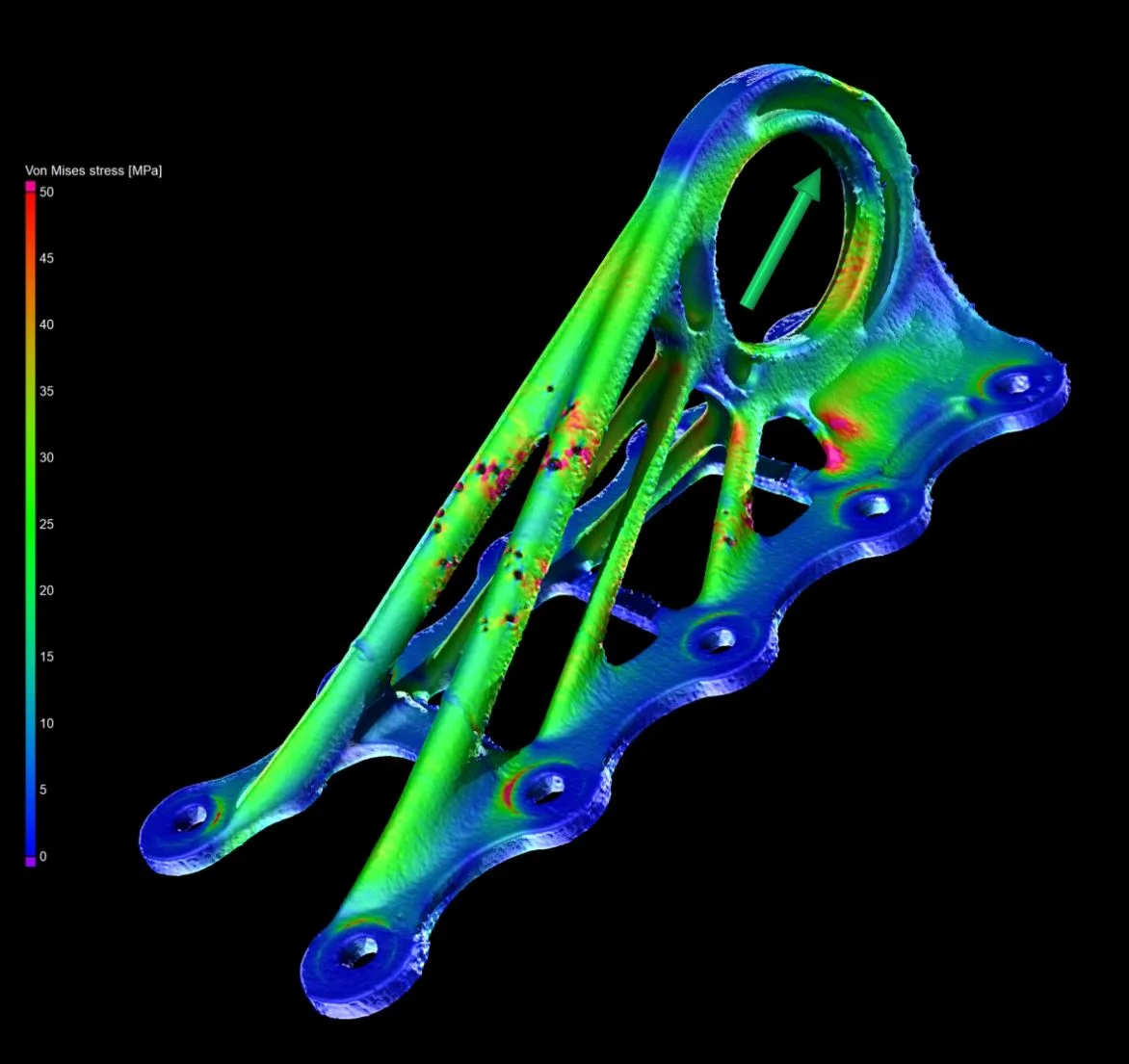

Stress analysis on a bionically optimized aeronautic structural bracket

Compressed material sample of open aluminum foam

Stress concentration at individual pores in a component

Loaded snake fang (Causus rhombeatus ) with visualized force lines showing the simulated bite force (Data from du Plessis, A., le Roux, S. G., & Broeckhoven, C. (2016), scan from Stellenbosch CT Scanner Facility)

Results

See your results directly on the scan of the real component:

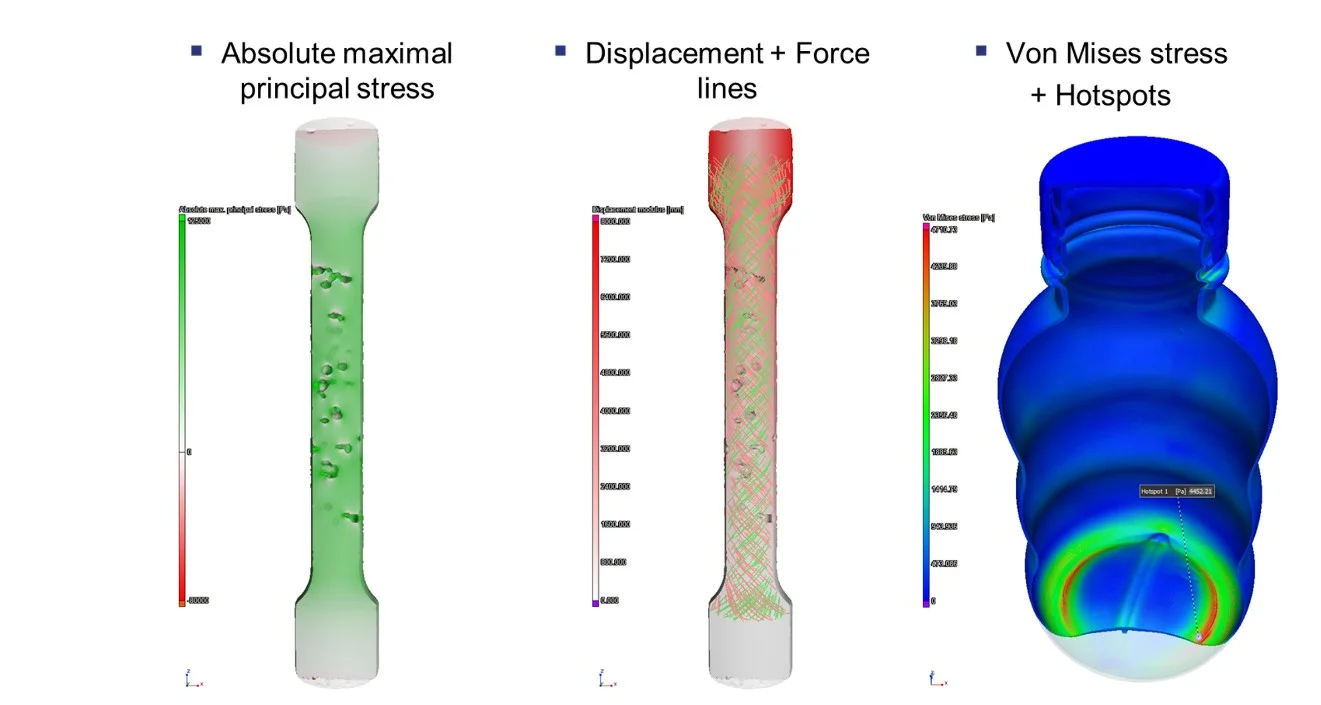

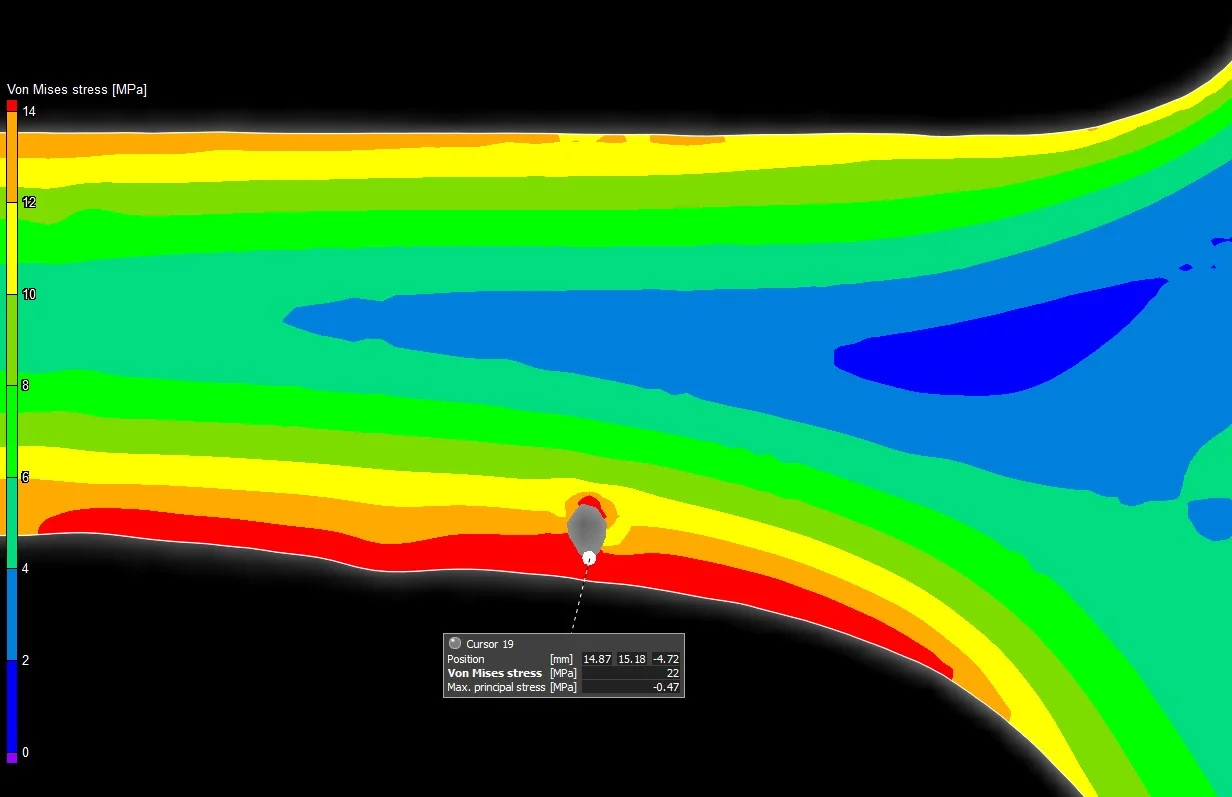

- Calculate and visualize von Mises stress and strain, and maximum principle stress for the evaluation of the plastic yield limit or estimation of rupture risk.

- Visualize the stress tensor field as force lines that illustrate the direction of the eigenvectors of the stress tensor with their length corresponding to the magnitude of the corresponding eigenvalue.

- Display the magnitude of displacement, color coded at each point in the calculated volume, to visualize the calculated deformation.

Stress Concentration at Hot Spots

Identify critically loaded areas in your part:

- Detect and visualize local maxima of von Mises stress, maximum shear stress, maximum principle stress, and detect magnitude of displacement.

- Identify and visualize connected areas in which the selected stress component or displacement exceed your specified threshold.

Detect and visualize local maxima of von Mises stress

Calculate the maximum value (hot spot) of a selected stress component

Comparison with CAD-Based Simulation

Compare simulation results based on the CT data of your actual part with simulations on the corresponding CAD model:

- Simulate both the CAD model and the actual part with all its discontinuities and shape deviations.

- Automatically compare two simulation results on the same or similar object for von Mises stress, maximum principle stress, maximum shear stress, or magnitude of displacement.

- Calculate the difference of the respective values for each point of the structure and visualize the color-coded results on the part.

Validated Results

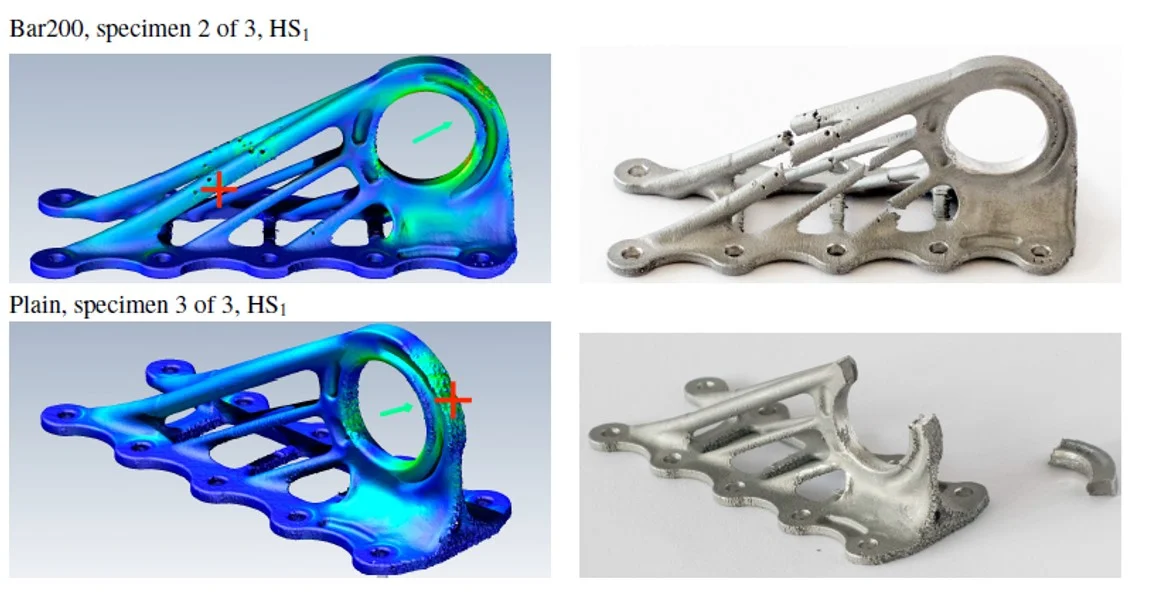

The simulation method in the Structural Mechanics Simulation Module has been numerically validated against conventional finite element analysis results and showed a good agreement. It has also been experimentally validated against physical tests which showed it is capable of identifying the most likely locations of failure in a structural component. (Predicting Failure in Additively Manufactured Parts Using X-Ray Computed Tomography and Simulation, Peer Reviewed Paper, 7th International Conference on Fatigue Design 2017)

Benefits

Low Effort

- No meshing required

- No simulation expertise required

- Seamless workflow from material segmentation and defect detection to simulation, all in one software

Realistic

- All microstructural details are captured by subvoxel-accurate material segmentation

- Simulated stresses can be directly related to the underlying material microstructure (e.g., size, location, and shape of pores or thicknesses of struts in open-cell foams)

Validated

- Predicted fracture locations and tensile strengths validated in experimental tensile tests of 3D-printed components with pores

- Effective elastic properties of a cubic lattice validated against a conventional FEM simulation